Tooling projects

This department allows us to improve not only customer service, but also to manufacture the molds and tools necessary to achieve the final product ourselves, which guarantees complete coordination between design and manufacturing, achieving the perfect rapport to achieve the best manufactured in any of our specialties.

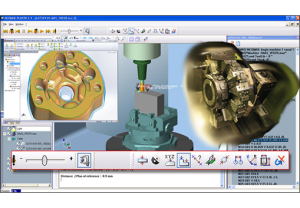

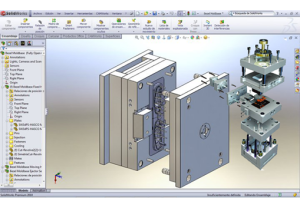

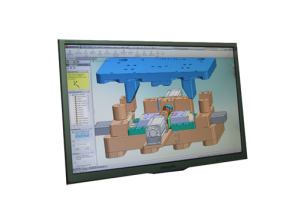

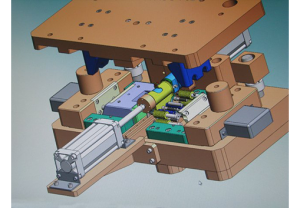

Manufacturing development is made by CAD (Computer Aided Design) 2D or 3D. Next, the programming of milling, turning or EDM is carried out by means of the CAM system (Computer Aided Manufacturing)

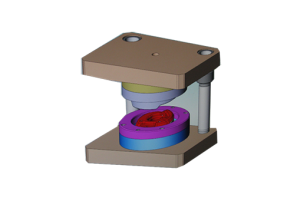

Moulding

- Die cutting and stamping.

- Plastic molds for injection or compression and for light alloys.

- Molds for thermoforming (Blister).

- Useful for assembly, verification and welding.

- Other types of molds or dies.

Maintenance and spare parts

INMER also offers a maintenance service for all types of tools, whether conventional or progressive, and manufactures parts due to wear or breakage, sharpening and tuning, etc.