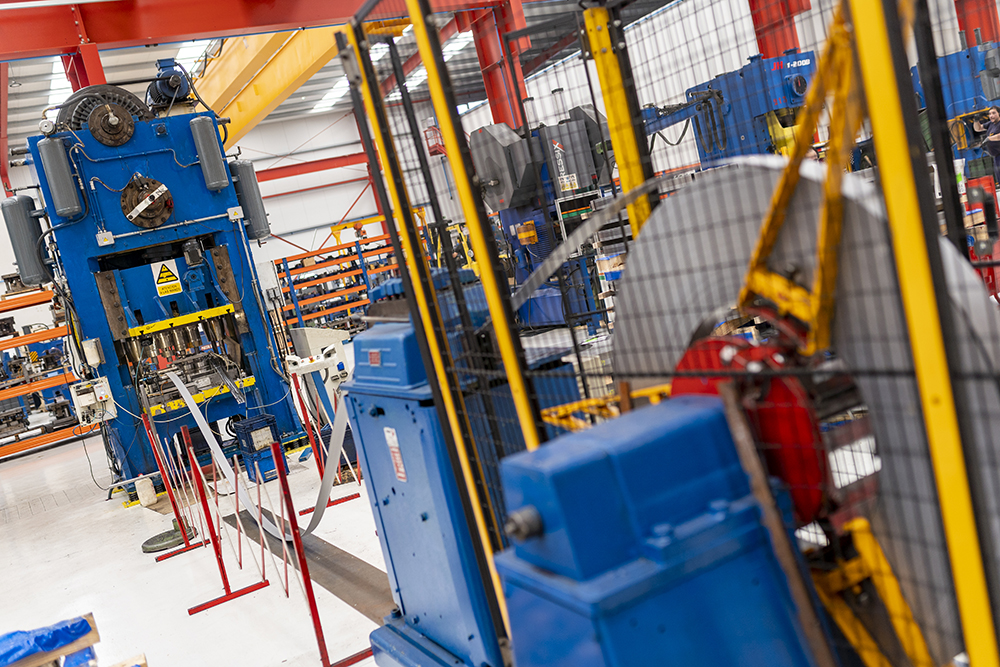

Stamping

We transform metallic sheet by stamping at different tonnaje presses by manual, progressive and transferred stamping.

Manual stamping

Completely manual blow-by-blow phased technology and also technology with manual die and automatic operation for certain types of parts.

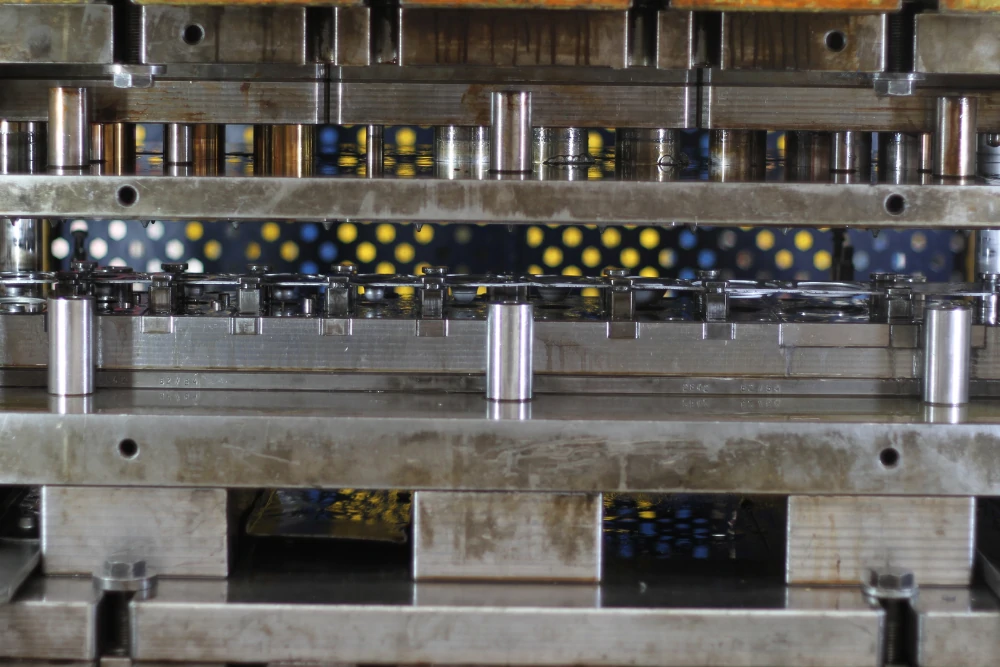

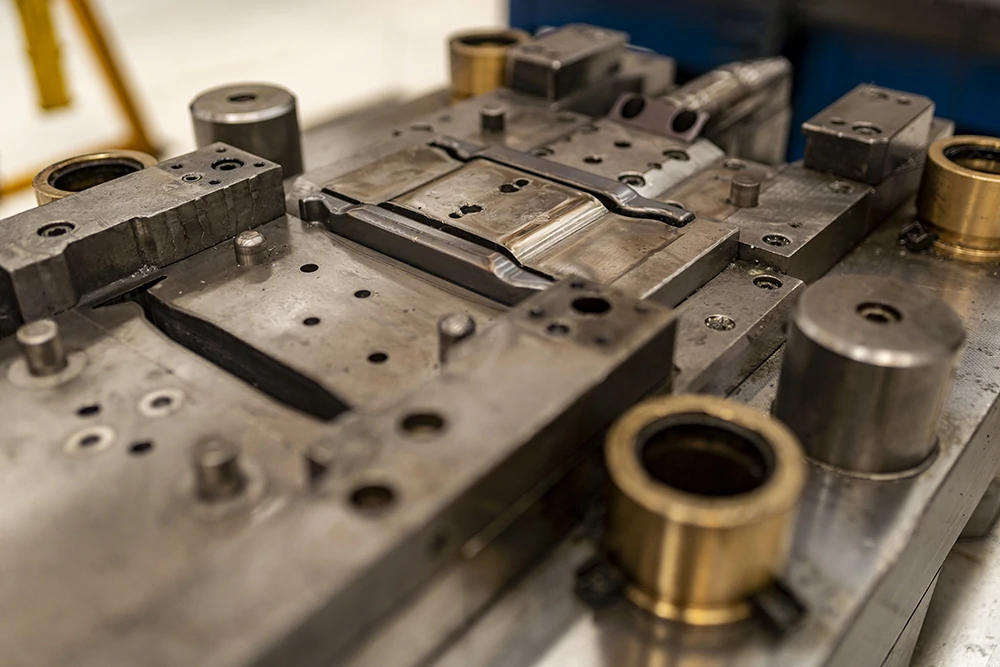

Progressive stamping

Design and manufacture our own progressive dies in order to optimize processes.

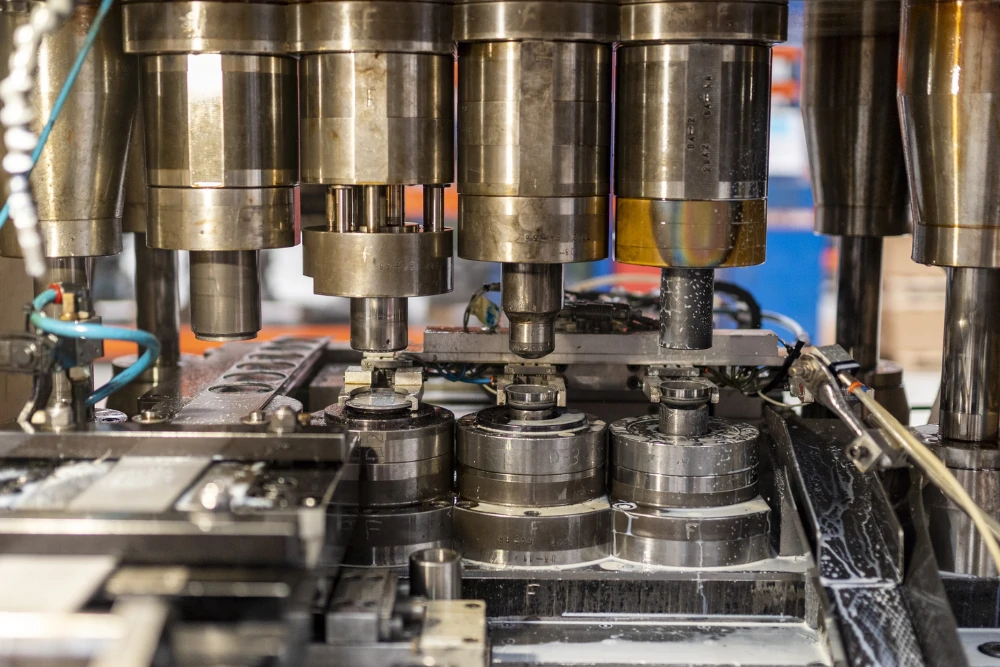

Transferred stamping

Transferred dies for the manufacture of automotive components.

Characteristics

- Cutting, stamping and folding presses

- Transformation of all types of metals in punching, bending, bending, riveting, welding, threading and drawing operations.

- Wide range of sizes and shapes

Poduction Means

- Eccentric presses between 10 and 400 Tn

- Variable speed automatic presses for progressive dies from 100 to 400 Tn

- Presses for transfer toolings from 60 to 300 Tn

Transformed materials

- Cold and hot rolled carbon steels, high elastic limit steels

- Galvanized, stainless and aluminum steels.

- Other materials starting in formats and coils.

Production capabilities

- Thicknesses up to 8mm

- Workpiece surface up to 500 x 300 mm